Module 5: Farm Machinery Safety

What does it mean when we say "farm machinery"?

Farm machinery typically refers to mechanized field equipment such as tractors or implements, including self-propelled implements, or any combination thereof used in agricultural operations. Tractors are the most common, and they have a variety of attachments/accessories to accomplish various tasks, including:

- Plowing

- Planting/seeding

- Fertilizing

- Pest control

- Irrigation

- Harvesting

- Mowing

- Baling

Hazard Recognition

Some of the most common hazards with farm machinery include vehicle overturns, operator/bystander run overs, power take-off incidents, stuck vehicles, and equipment failure.

Of those mentioned, overturns continue to be the leading cause of death involving farm machinery.

Overturns

Let's review some Basic Prinicples

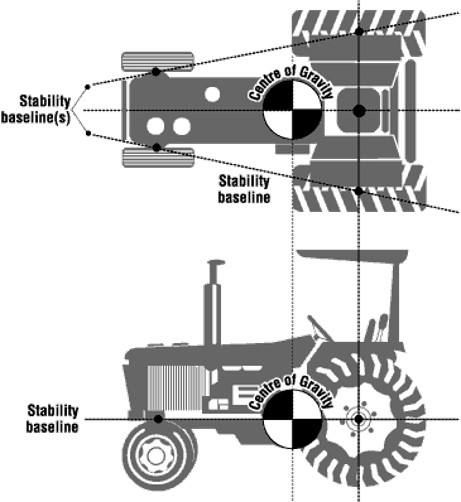

Stability Baseline is the imaginary line that runs inside the point where the wheels contact the ground.

Center of Gravity is the point at which the equipment is balanced and needs to stay inside the Stability Baseline.

The Stability Baseline (SB) and Center of Gravity (CG) work together to keep your equipment on it's wheels instead of the side. When the CG goes outside of the SB, bad things can happen.

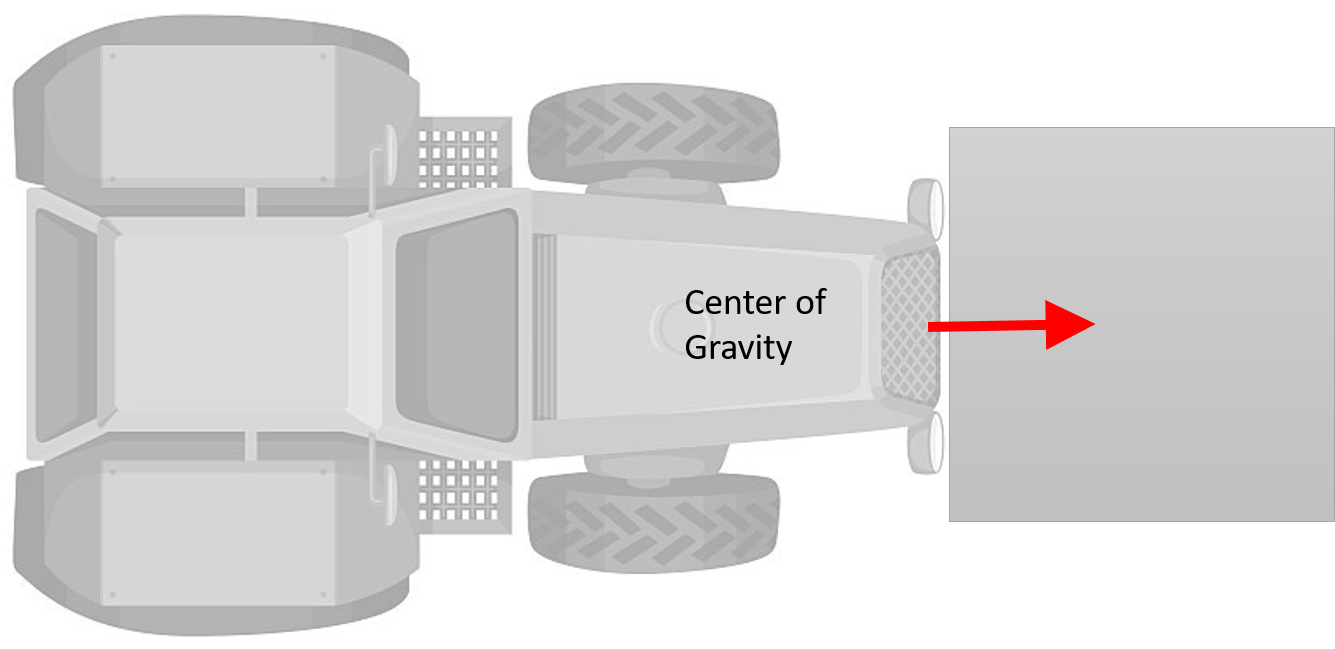

Knowing how a load on your equipment impacts the CG is critical. Whether you have bail of hay on the front or a sprayer tank on the back, that CG is going change. By how much? Depends.

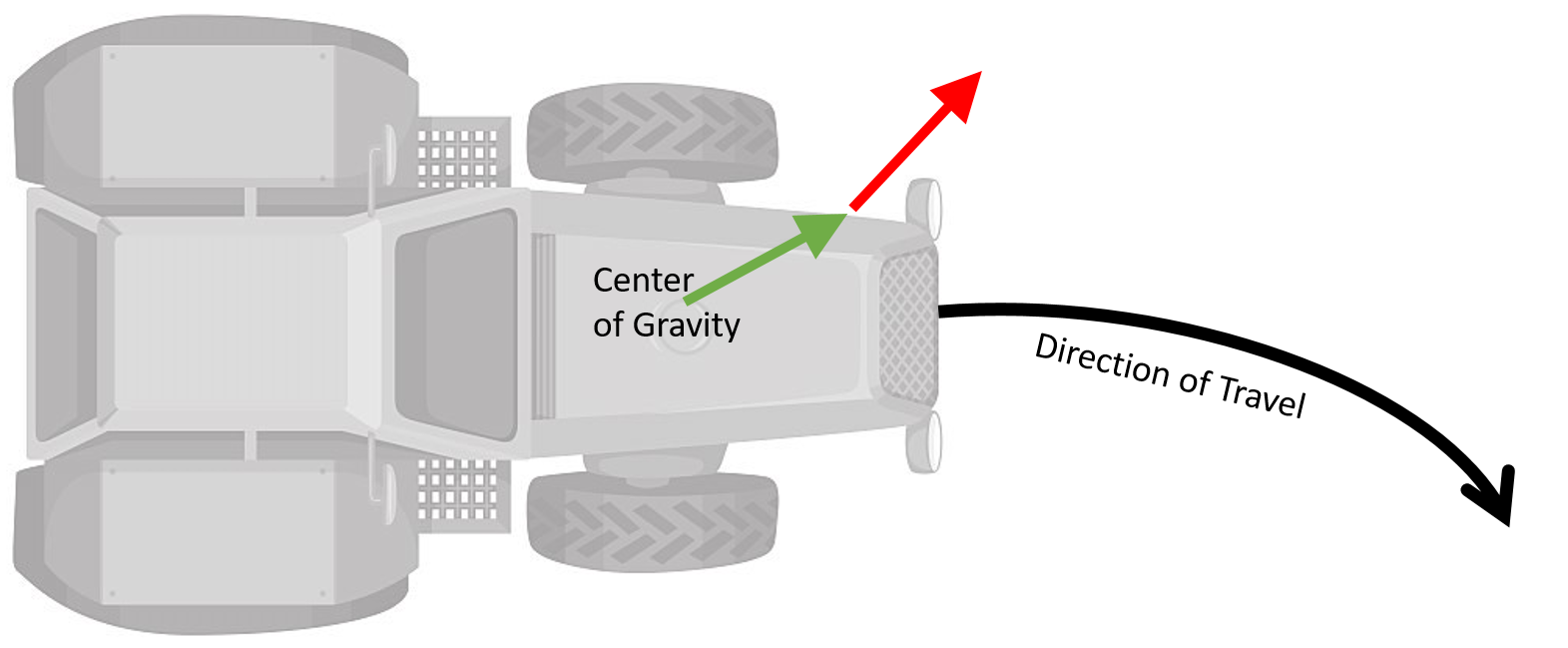

Once you start moving, that CG can move as well. When you turn the equipment, the CG of the load can shift and put you outside of the SB. Know the load and travel with loads as close to the ground as possible.

When traveling on a slope, your CG will shift. This impacts what's called the lateral stability. At all times you should travel at a safe speed and avoid quick steering manuvers. From the picture above you can see the CG is getting closer to the SB. It would not take much to move it outside of the SB.

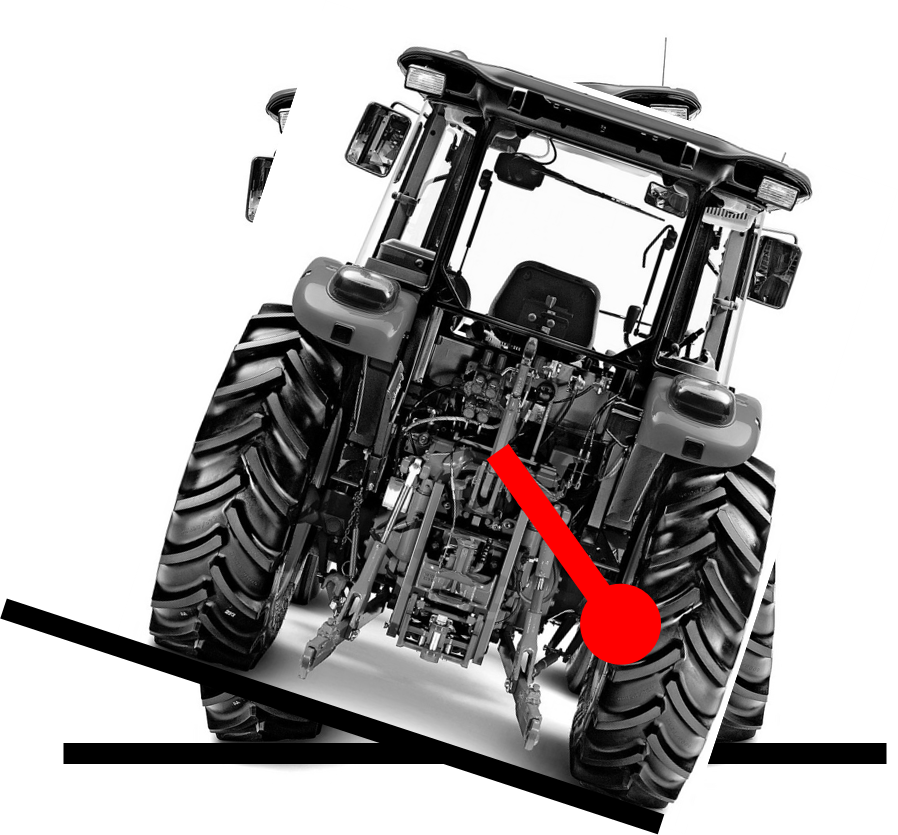

The longitudinal stability is the resistance to overturning to the front or the back. Usually caused by exceeding the maximum lifting capcity, extending a load too far, or going up or down an incline.

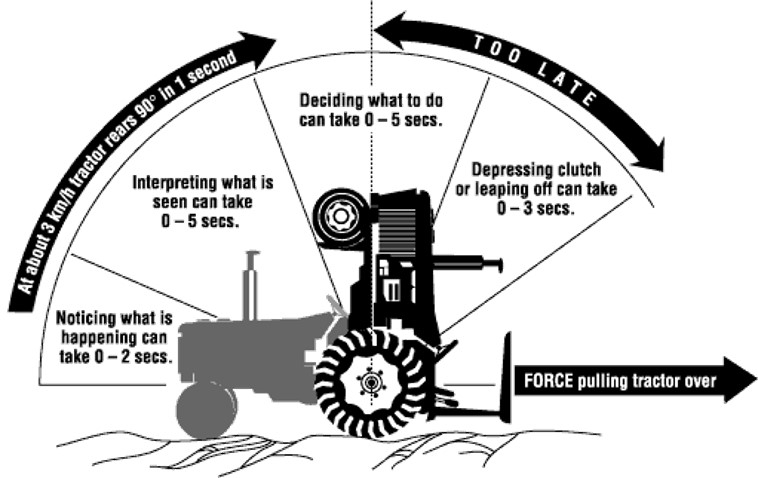

Rear rollovers happen so quickly that even if you recognize the problem, you don’t have time to react. Equipment can reach the “Point of No Return” in ¾ of a second. For many tractors, this point can be as little as 75 degrees from a level surface. Rear rollovers are less common but are deadly.

You increase the risk of a rear rollover anytime you attach a load anywhere other than the designed location; when backing downhill and applying brakes, or accelerating too rapidly.

Driving forward in mud, snow or ice can cause the rear axle to stop moving. The entire chassis can rotate around the rear axle, resulting in a rear overturn.

If you become stuck, “rocking” the equipment between forward and reverse can easily create a rear overturn so quickly you don’t have time to react.

Runovers

Getting off of farm machinery with the engine running is extremely dangerous. Anytime you dismount the equipment, turn it off.

When operating the equipment, be aware of who else is near you.

Power Take-offs and Rotating Parts

Rotating parts present a number of hazards. Even at slow speeds, rotating parts can have enough torque to pull you into the machine. Loose clothing can easily get caught, as evident in a fatality in 2022 on a Virginia farm, where a farmer was stepping over an unguarded power take-off shaft and his clothing became entangled. Mulitple injuries were sustained resulting in death. Injuries from rotataing equipment can lead to being crushing, amputations, and severe bleeding. These entanglements can be very complex.

Stuck Vehicles

Equipment can easily become stuck in mud or snow. Recovering a stuck vehicle is a dangerous process that can result in serious injury or death. Recovering stuck vehicles and equipment is a specialized task. Using chains or tow straps instead of a recovery strap is common mistake. Recovery straps, sometimes referred to as a "snatch strap", are designed to recover a vehicle that is stuck (as opposed to a tow strap which is designed to pull another vehichle that is not stuck). The materials used for the two different types, as well as the abilities of the materials or fabrics, is different. Recovery straps are designed to stretch, similar to a rubber band, and are rated for the capacity of the vehicle to be recovered. When a chain or inappropriate strap breaks, it can injure or kill anyone within range. Check out this guide for more information on "Extracting Stuck Equipment". If you do not feel you can safely recover stuck equipment, contact a wrecker or recovery service.

Equipment Failure

Power transmission on farm machinery typically occurs with a combination of belts, chains, drive shafts and gears.

Hazards can include:

- Amputations, crush injuries or entrapment of hands and arms.

- Injuries from being pulled into the machine’s power transmission or points of operation.

Hydraulic systems operate at high pressure. Hazards can include:

- Hydraulic needle injury from pinhole leaks in hoses;

- Burns from hot, high or low pressure fluid leaks from containers, connections or cylinders; and

- Bruises, blunt trauma or crush injuries from the uncontrolled release of energy from tools or parts under pressure.

Evaluating the Hazards

Equipment inspections to ensure it is ready to use and safe to use is paramount.

Equipment should be inspected daily before use, after any extended breaks, and when changing attachments. Remember to use caution when checking for leaks in pressurized hydraulic lines.

Evaluate where you are working that day too. Weather can change conditions from day-to-day. Hidden obstacles in the area can cause unexpected problems.

Hazard Controls

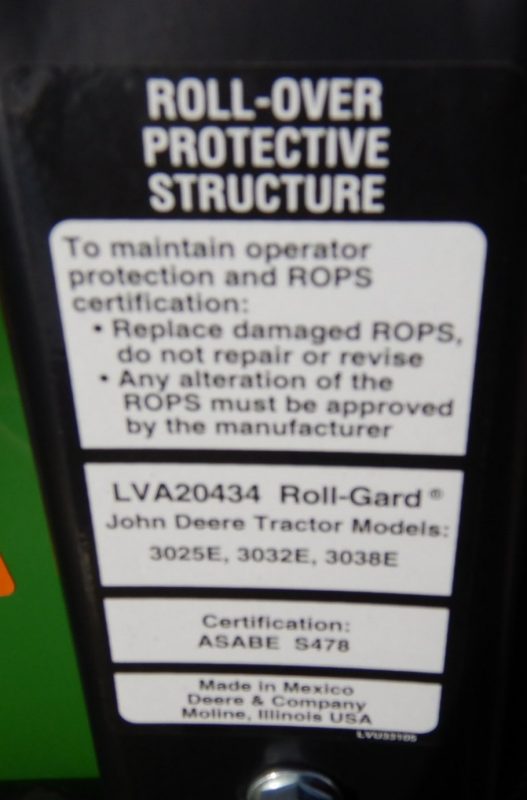

Maintaining your equipment is critical to safe operations. Equipment should be serviced and maintained according to the manufacturer’s instructions. Any modifications or repairs should only be done with manufacturer approval.

Rollover Protection Systems (ROPS) have been standard on tractors since 1985. ROPS are designed to limit a rollover to 90 degrees in a direction. ROPS are only effective if the operator is using a seat belt and stays within the ROPS protected zone.

There are limited exceptions to the ROPS standard. This include tractors that are 20 HP or less, low-profile tractors, or tractors mounted with equipment incompatible with ROPS use.

Doors, guards or covers that shield power transmission and points of operation should only be opened when the machinery is powered off and all hazardous energy is controlled.

Ensure all sources of energy are controlled when the tractor is not in operation. Set brakes, turn off the PTO, lower all loads, and power down the tractor. Secure the key before performing any work on the tractor or attachment.

Driving on public roadways is extremely dangerous.

- Turn on your hazard flashers.

- Ensure all lighting is working.

- The slow moving vehicle emblem must be prominently displayed.

- If a trailing an implement, the emblem should be on displayed on the back of the implement.

- Escort vehicles can be used.

Noise from tractors and farm implements can range from 92-105 decibels, even in an enclosed cab. Without protection, hearing can be damaged quickly. Use hearing protection appropriate for the equipment you are operating.

Hitch Safety

Most equipment is designed to safely counteract the rearward tipping action of a pulled load if and only if the load is attached to the correct point, typically a drawbar. When loads are attached to any other point, the equipment’s safety measures are defeated and you are at risk of a rollover. Always hitch to the proper location as specified in the tractor operator’s manual.