Abrasive Wheel Machinery Safety Checklist

Abrasive Wheels Machinery Safety Checklist

Always follow manufacturer's instructions and recommendations for safe and proper use.

Flanges

- Are all flanges maintained in good condition?

- When the bearing surfaces become worn, warped, sprung, or damaged, are they trued or refaced?

Mounting inspection

- Immediately before mounting, are wheels closely inspected and sounded by the user (ring test) to make sure they have not been damaged in transit, storage, or otherwise?

- Immediately before mounting, is the spindle speed of the machine checked to be certain that it does not exceed the maximum operating speed marked on the wheel?

- If the wheels sound cracked, are they not used?

- Are the wheels dry and free from sawdust when applying the ring test, (otherwise the sound will be deadened)?

Guarding

- Is the work rest adjusted to 1/8” from the bottom of the wheel?

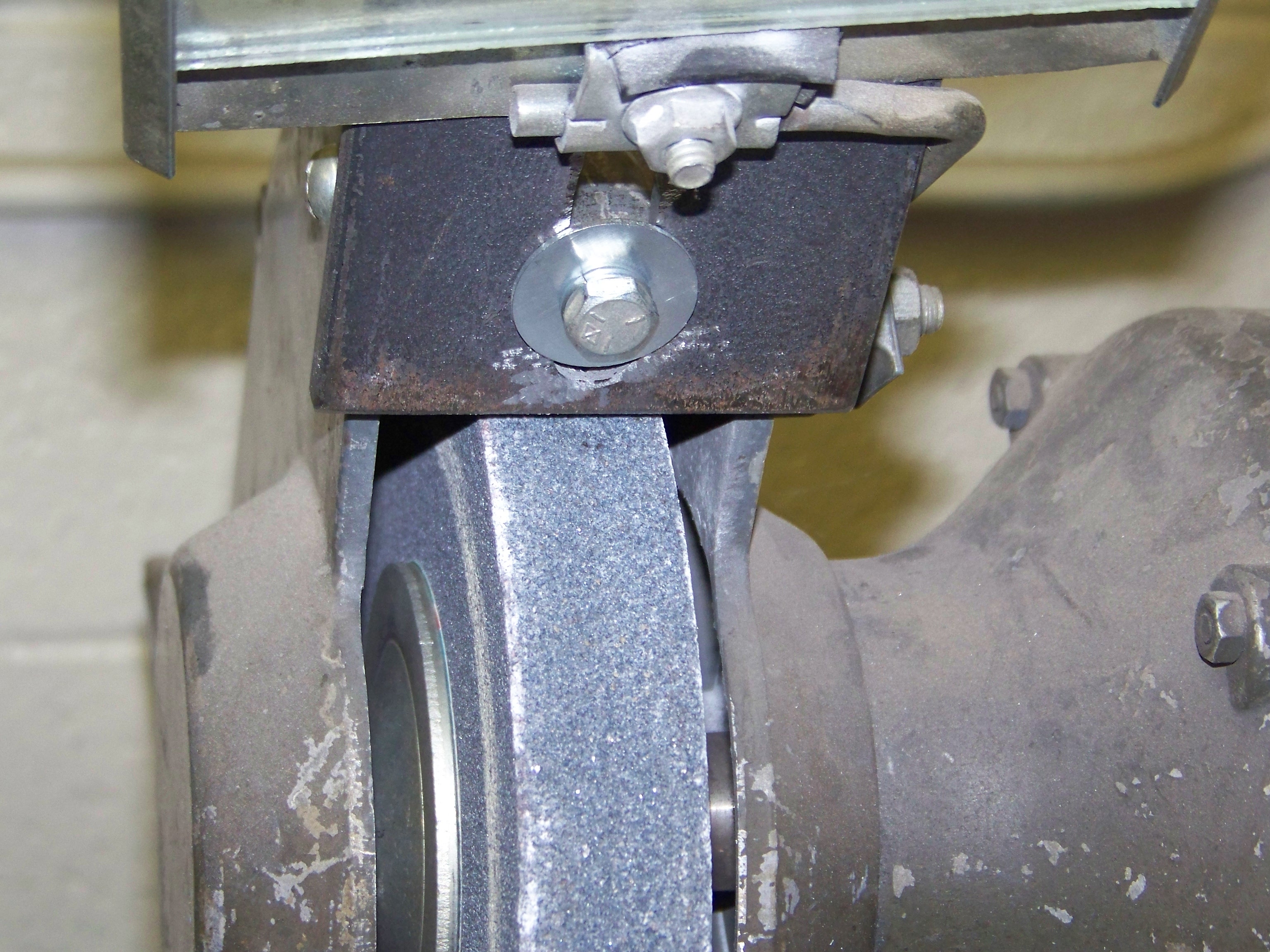

- Is the tongue guard adjusted to ¼” from the top of the wheel? See picture below.